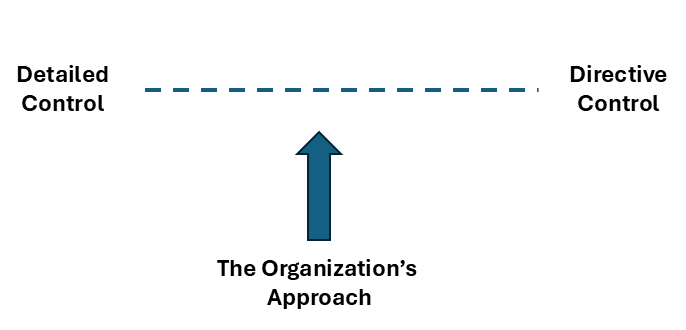

As organizations work to design and develop a quality management system (QMS), how to establish compliance becomes a key consideration. The choice of structure represents a continuum between two types of control

- Detailed Control – detailed procedures, work instructions and templates that define the mechanisms for compliance

- Directive Control – the procedures detail the desired outcomes, and the executing organizations define processes in accordance with these desired outcomes.

Many factors influence the choice of control, and the right choice requires considering all of these factors. This choice may be a hybrid, incorporating elements of each approach.

Examples of Directive and Detailed Control

As an example of detailed control, the QMS is based upon procedures that specify in great detail the actions, owners and outputs of QMS related activities. Procedures contain phrasing such as

The program manager shall be responsible for developing a project plan in accordance with Template T-XXX and updating the plan at every phase milestone.

In a more directive based QMS, the project plan template may contain phrasing such as

In this part of the plan, the project team should detail the process for updating the project plan.

Detailed control describes the process in detail in the procedures, and the project and functional teams follow this prescribed “recipe”. With directive control, the project teams establish processes to ensure that their work is compliant with the overall goals of the QMS.

Key Factors in Establishing the Type or Control

Directive versus Detailed control involves establishing a number of factors, and ultimately the result is a point on the continuum (from Cutting Our Feet- January-February 2017 – English Edition – Military Review).

Key considerations in making the decision of where to place the QMS on this continuum include

Information Flow and Situational Change

Evaluating the rate of change that the organization experiences should be the first consideration in deciding the type of control within the QMS. For organizations or activities that are dynamic and subject to frequent change, directive control may be a better choice. For organizations engaged in repetitive, highly controlled activities, more detailed control may be better. Other considerations such the type of product (high volume disposable products versus high tech low volume products) also come into play.

In situations where activities may be both dynamic and repetitive, a hybrid approach to the QMS may be an option. An example of a hybrid approach may be to have detailed control for manufacturing activities, while allowing more directive controls for R&D activities.

In addition to evaluating the level of change the organization experiences, review the mechanisms for the informational flow within the organization. When the groups within the organization are separate, and good information flow to upper management is not in place, a directive control allows each group to adapt to their situation. In this situation, each group develops local plans to address the QMS processes and controls. When good information flow exists, a more detailed QMS process can be supported.

The QMS needs to be flexible in organizations with a great deal of situational change, such as product development with software and field upgrades. When the organization has low levels of change, such as manufacturing, detailed control may be better.

Organizational Maturity

Directive control requires a more mature and cohesive organization. The expectation is that the team will be aware of the overall goal and will have the maturity to define the processes for executing to meet the goal. In organizations with less maturity, detailed control has advantages.

Training

Detailed control requires more formal training on an ongoing basis. The members of the organization will need to develop the detailed procedures and associated training and drive this training. Organizations cannot assume that training for a detailed control QMS can be “read and understand”. The lack of focused training for detail oriented procedures results in situations where the details are ignored, and the result is that no overall control is in place.

Leadership

When implementing a QMS, consider the type of leadership within the organization. Detailed and directive control require very different skill sets. Management decisions to “move the needle” with respect to the level of control may require extensive organizational change management.

Final Thoughts

Most organizations have an understanding of the different levels of control, and the factors that will determine successful QMS. What organizations most often miss is the overall understanding of the continuum between directive and detailed control. The organizations fail to systematically evaluate the choices based upon the key factors outlined above.

Without a systematic evaluation, the organization may set the level of control in the QMS incorrectly. This can lead to some of the following failure modes

- Slow and ineffective new product development. Application of too much detailed control in the development process can limit the flexibility for the product development team to respond to changes in the project scope and direction.

- Poor Product Quality – lack of proper detailed control, and the training and monitoring this control requires, leads to poor product quality. People don’t follow the “recipe”, and adequate controls are not in place to detect the issues.

- Organizational Churn and Turnover – Control that does not match the organization leads to attrition. As an example, software developers don’t respond well to an overly prescriptive process, and turnover will be high.

Further Reading

Cutting Our Feet- January-February 2017 – English Edition – Military Review

Command and Control Theory (https://irp.fas.org/doddir/usmc/mcdp6/ch2.htm)

TGFR Consulting LLC

TGFR Consulting LLC